The Production of Ink in Najd refers to the methods of ink-making that were passed down among students of knowledge and scribes in Najd during the era of the First and Second Saudi States through practice and tradition. At that time, the Najdi environment was rich in various types of plants and trees from which different kinds of ink were extracted. In addition, they relied on the residues of fire and smoke. Their ink production methods were primitive and simple, without precise measurements or controlled compositions of colors and their compounds.

Production of black ink in Najd

Black ink in Najd was made from both organic and inorganic materials. Organic materials were extracted from trees and plants, including their fruits and leaves, which were also used to produce dyes and colors for purposes other than writing. Black ink was specifically made from the Dyer's Croton tree (Chrozophora tinctoria), known in Najd as Udhun al-Himar or Katm. Another plant serving the same purpose was the seeds produced by the Balsam tree (Commiphora gileadensis). Additionally, pomegranate tree (Punica granatum) bark, as well as the residue left from the burning of various trees, which adhered to the outer surfaces of copper pots and utensils, were also used in ink production.

The ink was mixed with a small amount of salt and gum extracted from the Red Acacia (Vachellia seyal) or the Gum Arabic Tree (Vachellia nilotica), after being cooked together in a single vessel with water until the ink was ready for writing. It was then removed from the heat and cut into small pieces before completely cooling. These pieces were left to dry and harden, making them easier to store in dry places. When needed, the writer would select a sufficient number of these small pieces, place them in the inkwell, and add water until they dissolved.

As for the inorganic materials used in writing, they were limited to a single type: the black substance produced by combustion. In Najd, this material was known by various names. In al-Arid, it was called al-Sunun, while in al-Washm and al-Quway‘iyah, it was referred to as al-Sana or al-Sanu. It was also identified by its appearance, being called Sawad al-Kudur or Sana al-Kudur.

Production of colored inks in Najd

The people of Najd were familiar with the production of colored inks, which were made from materials readily available in the Najdi environment, rich in plants from which colors were extracted. The colors used by the people of Najd in their manuscripts, as well as in the decoration and embellishment of doors, windows, walls, and other surfaces, included red, yellow, green, and various shades of blue.

Red ink

Red ink was made using saffron, which was the primary ingredient in its production. Saffron has been known since the emergence of Arab-Islamic civilization and the practice of book copying and circulation. Additionally, pomegranate peel was used to extract a reddish color, which sometimes leaned toward yellow. Another source of red ink was henna leaves; when diluted with water and mixed with gum arabic, it produced a red ink that was not deep crimson but rather had yellowish or sometimes orange undertones.

Yellow ink

The people of Najd prepared yellow ink using pure saffron or by mixing it with pomegranate peel, in addition to combining both with gum arabic. Some scribes also used turmeric and safflower to produce a highly intense yellow ink. The process involved finely grinding the material, then boiling it with water over heat until it thickened. A small amount of salt and gum was then added, making the ink suitable for writing. Once cooled, it was cut into small pieces of various shapes for easy storage.

Green ink

The primary ingredient in the production of this type of ink was the powdered henna plant. However, green ink was rarely used for writing. Its production was not particularly difficult for professionals, but it required precision in measuring and distributing its components. The ink was made by crushing henna leaves and then cooking them with a small amount of water. Gum arabic was then added until the mixture was nearly dry, after which it was cut into small pieces and stored for later use. Green ink could also be produced using inorganic materials. One method involved using verdigris (copper acetate), which was crushed and soaked in vinegar and lemon juice until it dissolved. Finely ground saffron was then added in an amount sufficient to blend with dissolved gum arabic, making the ink ready for use. Another method involved thoroughly grinding verdigris with gum arabic dissolved in gallnut water, then adding a small amount of vinegar before writing with it.

Blue ink

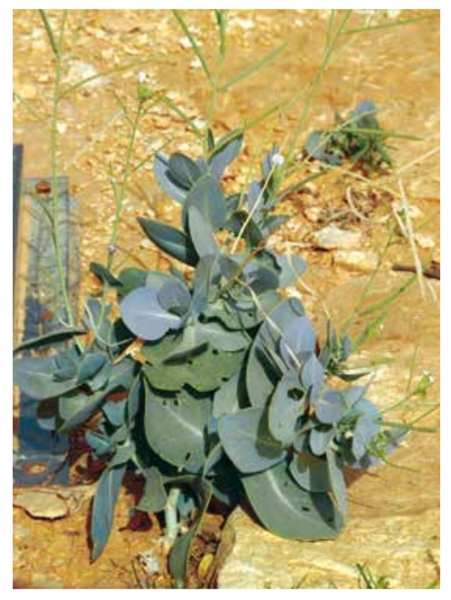

Indigo blue was often the primary substance used to produce blue ink, after being diluted with water and mixed with gum arabic. Additionally, the people of Najd also made this type of ink from the Balsam tree, which predominantly grows in the northern parts of Najd. The process involved collecting the seeds produced by the tree, drying them under the sun, then grinding them into a fine powder. The powder was then cooked to extract the blue ink.

Related quizzes

Related articles